Energy Efficiency & Onsite Generation in Industrial Spaces

Energy often represents 30–50% of an industrial facility’s operating budget and a major opportunity for savings. Today’s technologies let you generate power on-site, slash consumption, and leverage data for continuous improvement. Here are three high-impact approaches.

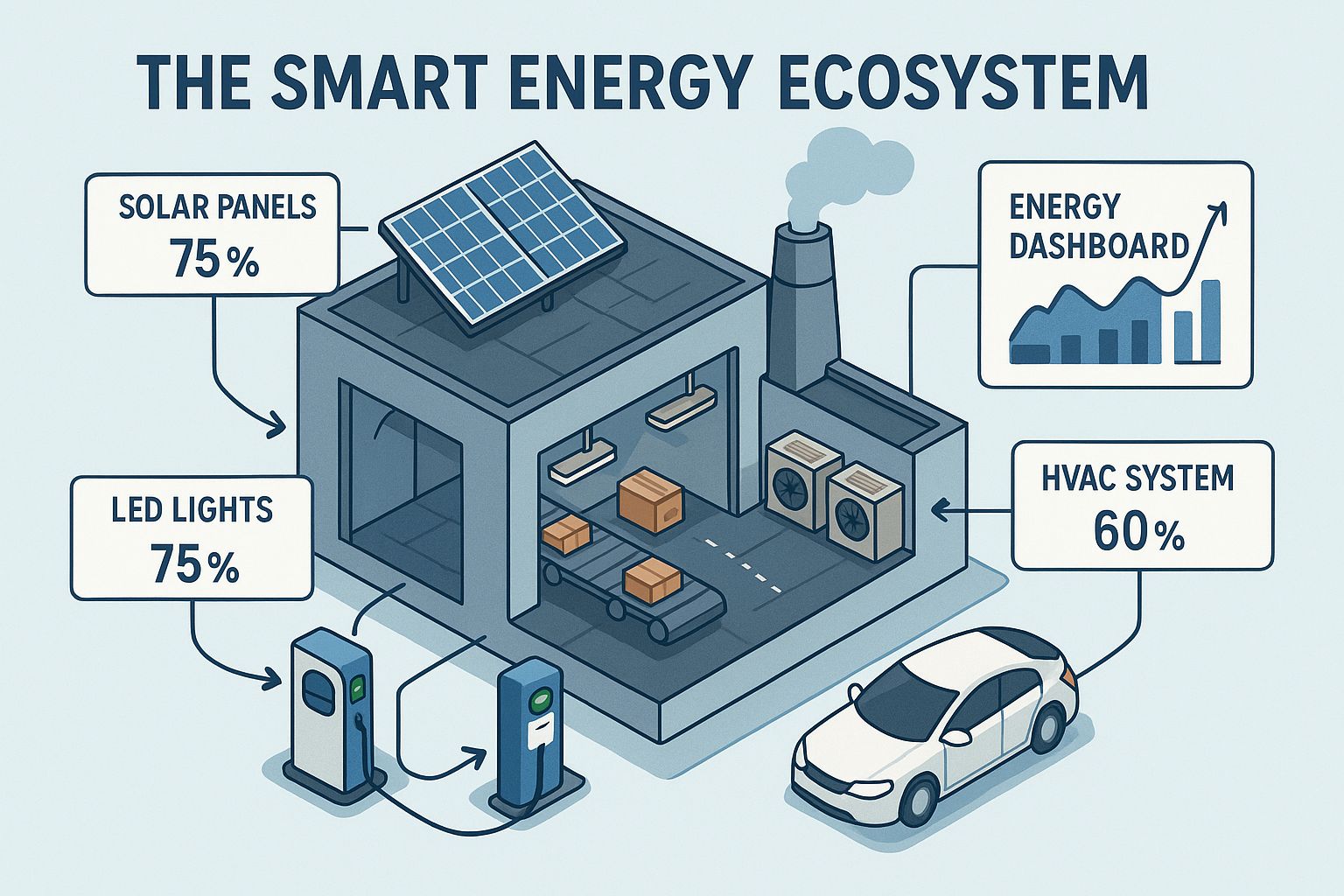

1. Solar Power & BIPV

Your roof and facades are untapped solar real estate:

- PV Arrays: Standard panels offset up to 60% of daytime demand; typical payback is 3–5 years.

- BIPV Solutions: Integrate solar cells into roof panels or curtain walls saving on both materials and installation.

- EV Charging: Power forklifts and fleet vehicles directly from your own system, reducing peak-demand charges.

Solar isn’t just green—it’s good business.

2. High-Efficiency Lighting & HVAC

Upgrading legacy equipment delivers immediate ROI:

- LED Lighting: Uses up to 75% less power, lasts 3–5X longer, and improves light quality.

- Smart Controls: Motion sensors and daylight harvesting can trim lighting energy by 30–50%.

- Advanced HVAC: Variable-speed drives and heat reclaim systems can cut heating and cooling costs by 20–35%.

These upgrades often pay back in under two years and improves worker comfort.

3. Intelligent Energy Management

What gets measured gets managed:

- Sub-Metering: Track usage by process, shift, or zone to pinpoint inefficiencies.

- Dashboards: Real-time analytics reveal spikes, wasted cycles, and load-shifting opportunities.

- Predictive Maintenance: AI-driven alerts keep equipment running at peak efficiency and avoid costly downtimes.

Continuous optimization turns savings into a culture.

Conclusion

On-site generation and efficiency upgrades aren’t optional, they’re essential for competitive, sustainable operations. At Form & Function Architects, we integrate energy-smart design from master planning through commissioning.

Ready to power up your productivity? Let’s discuss your energy strategy today.