Design & Construction Strategies for Sustainable Industrial Buildings

The eco-credentials of an industrial building are set from day one, during design and construction. By choosing the right materials, prefabrication methods, and building envelopes, you can dramatically reduce carbon footprints, accelerate schedules, and lower total costs. Here are four proven strategies.

1. Low-Embodied-Carbon Materials

Embodied carbon emissions tied to producing materials can account for up to 30% of a building’s lifetime footprint. To cut it:

- Concrete Blends: Use fly-ash or slag in place of pure cement to reduce CO₂ output by 25–40%.

- Recycled Steel: Electric-arc furnace steel reuses scrap, offering the same strength with far less carbon.

- Engineered Timber: Cross-laminated panels are a lightweight, lower-carbon alternative in non-structural zones.

Every percentage point reduced here pays dividends over the building’s life.

2. Prefabrication & Modular Construction

Shifting work off-site delivers cleaner, faster, and safer builds:

- Waste Reduction: Factory precision cuts site waste by up to 90%.

- Energy Savings: Pre-insulated modules arrive air-tight, reducing on-site heating and cooling needs.

- Speed: Faster installation means less disruption and lower labor costs.

Prefabrication isn’t just a trend, it’s a high ROI solution.

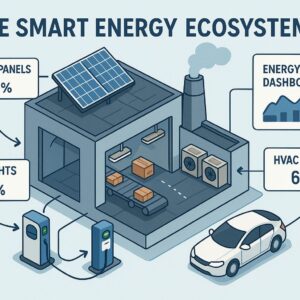

3. High-Performance Envelopes

Your walls, roof, and windows are your first defense against energy loss:

- Insulation: Aim for R-values that exceed code minimums to lock in comfort.

- Reflective Roofs & Green Roofs: Both cut cooling loads, one with high-albedo coatings, the other with living vegetation.

- Smart Glazing: Low-e or dynamic-tint windows manage solar gain, shaving 10–25% off HVAC loads.

- BIPV Elements: Integrate photovoltaics into cladding or canopies to dual-purpose your envelope.

Together, these measures can halve your heating and cooling costs.

4. Certification Roadmaps

Third-party ratings keep you honest and marketable:

- LEED: The global gold standard for energy, water, materials, and indoor environment.

- IGBC: Tailors credits to India’s climate and industrial context.

- GRIHA: Focuses on resource efficiency in emerging markets.

Pursuing certification guides decision-making, validates outcomes, and signals your commitment to stakeholders.

Conclusion

Well-chosen materials, prefab methods, and smart enclosures pave the way to lower carbon, faster delivery, and lasting performance. Form & Function Architects can help you embed these strategies from day one—delivering both green credentials and bottom-line impact.

Let’s talk about your next sustainable industrial project.